We deals only in bulk quantity

"Dealers & Bulk Buyer are welcome"

Morbi-ICPL is a leading B2B platform specializing in high-quality ceramic tiles and construction materials. As part of Ishan Ceramics Pvt Ltd, we cater to bulk buyers, ensuring competitive pricing, seamless ordering, and expert guidance. With our deep market expertise and strong manufacturer relationships, we deliver cost-effective and innovative solutions to businesses across India.

GET IN TOUCH WITH US

- Over 30 years of experience

- Direct manufacturer relationships

- Wide selection of ceramic tiles

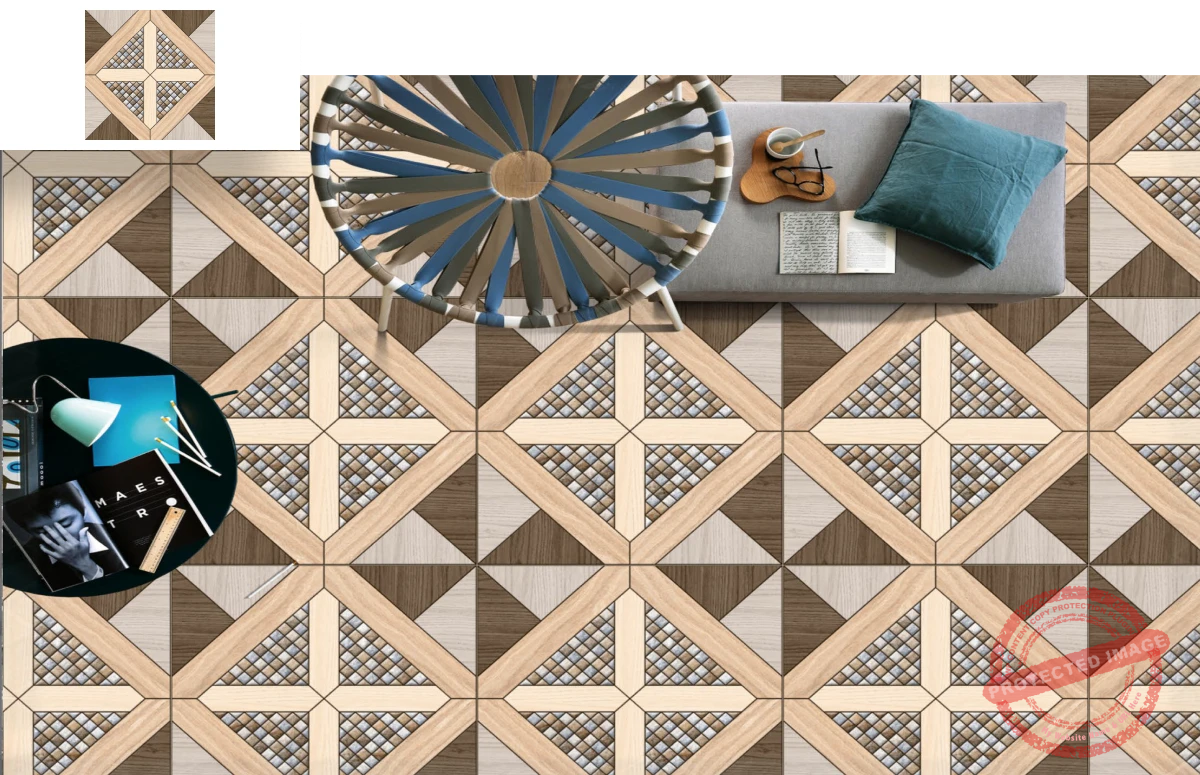

Product Portfolio

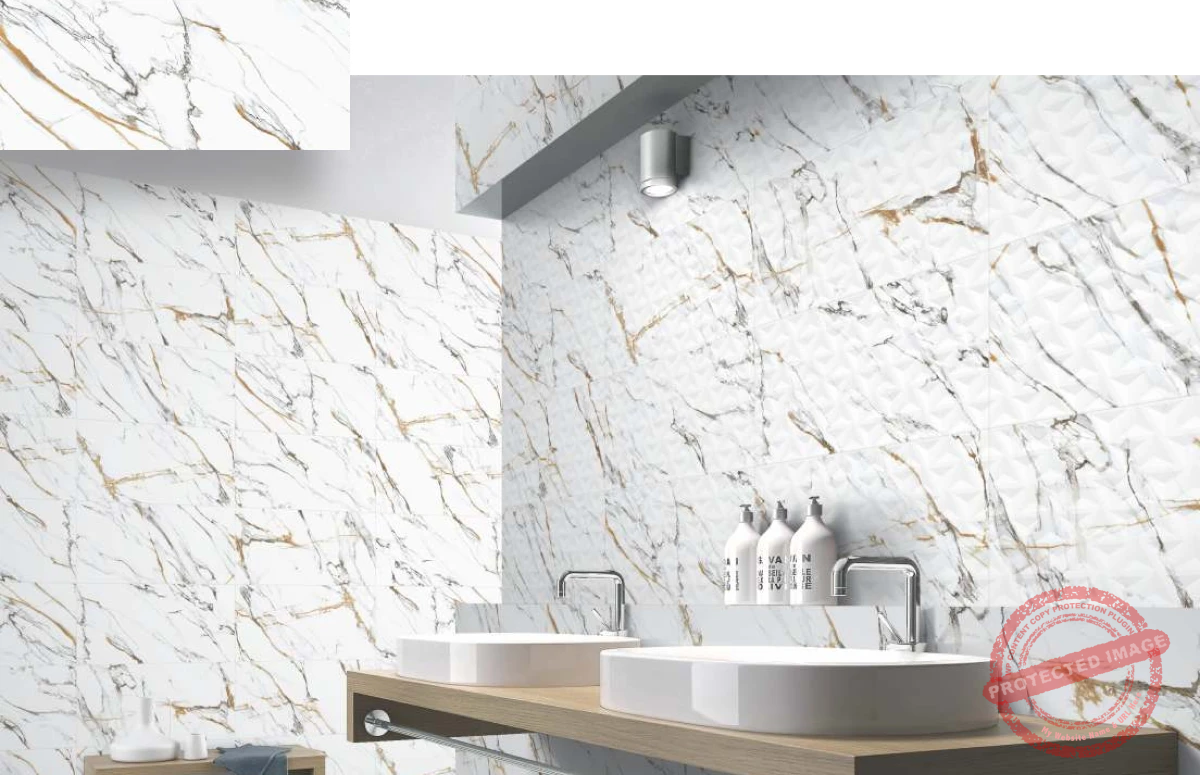

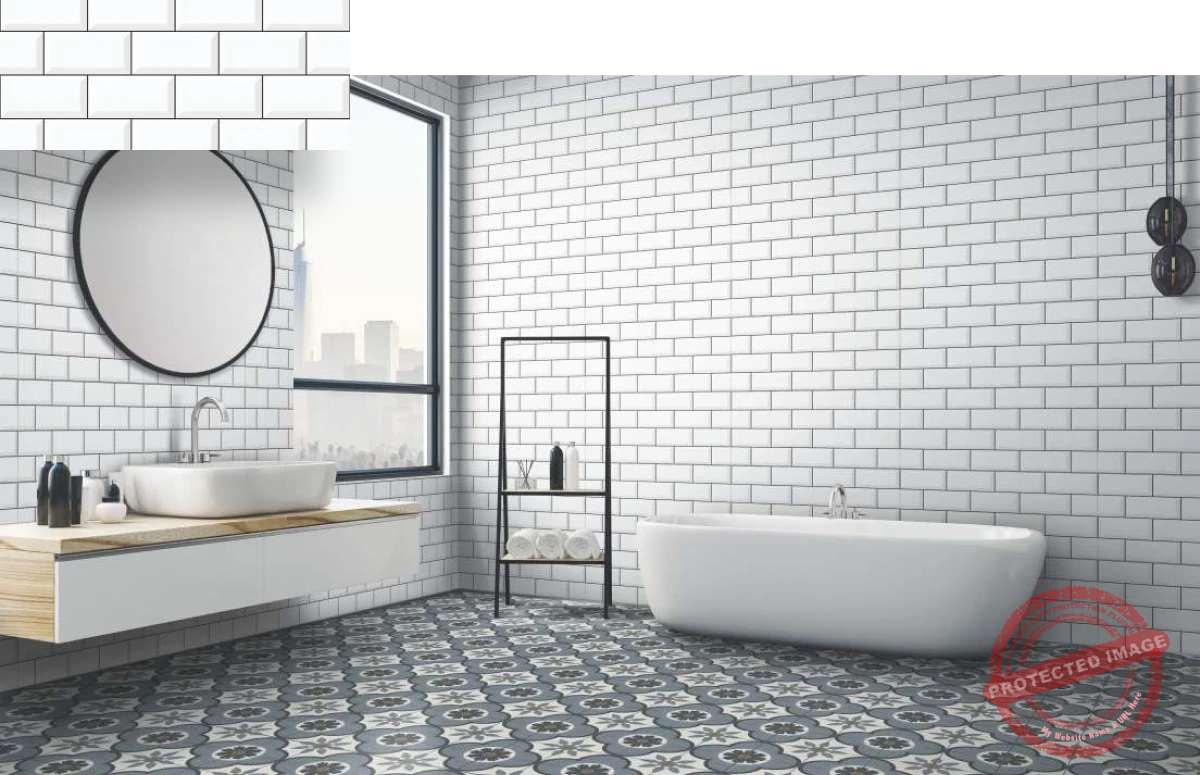

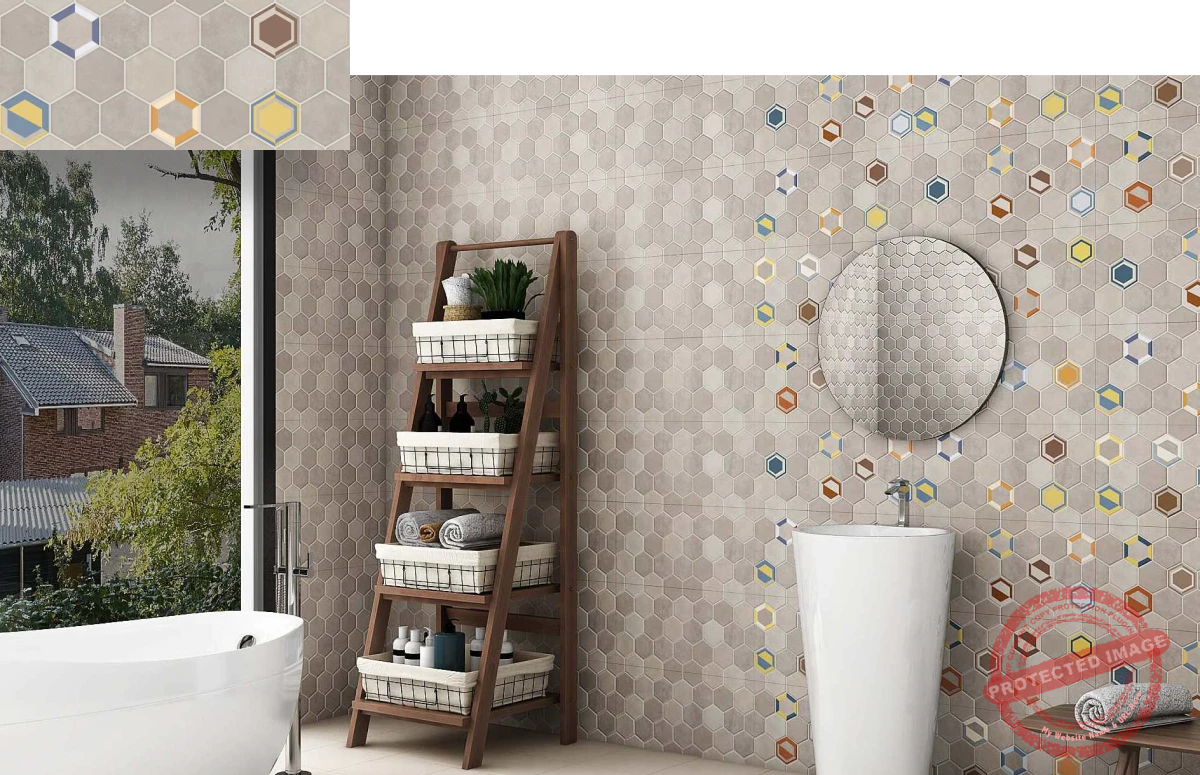

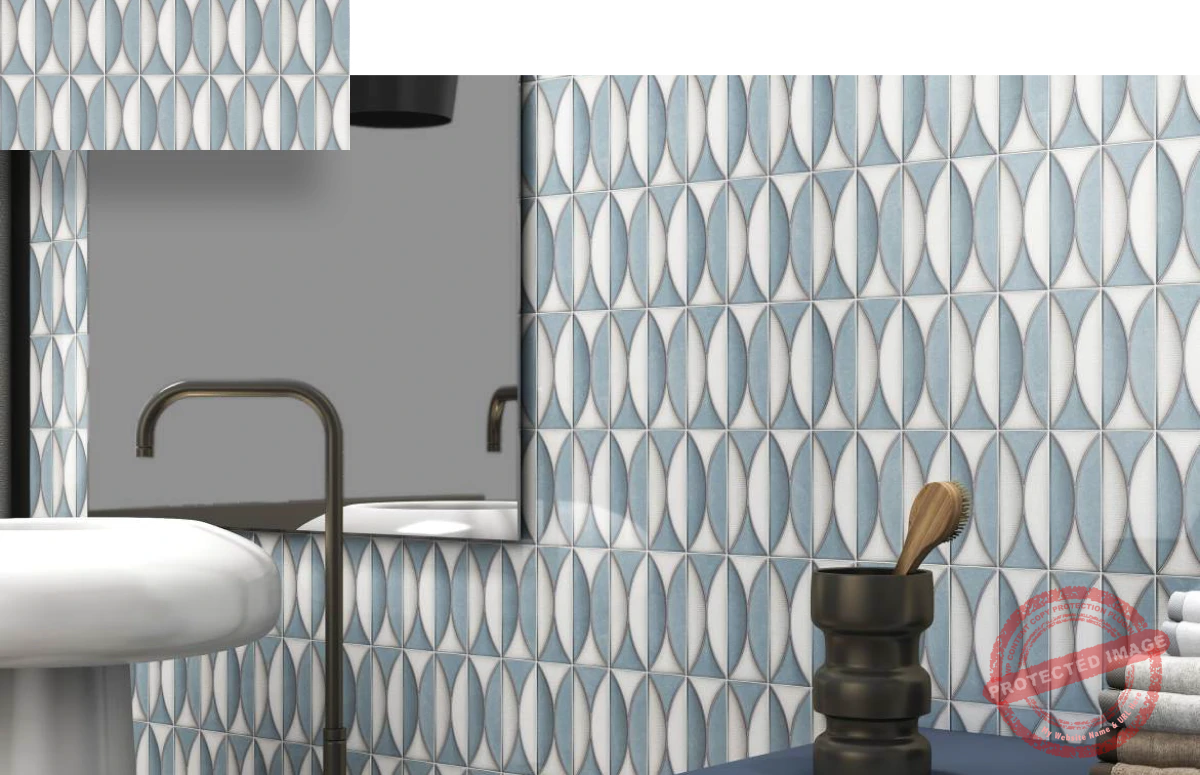

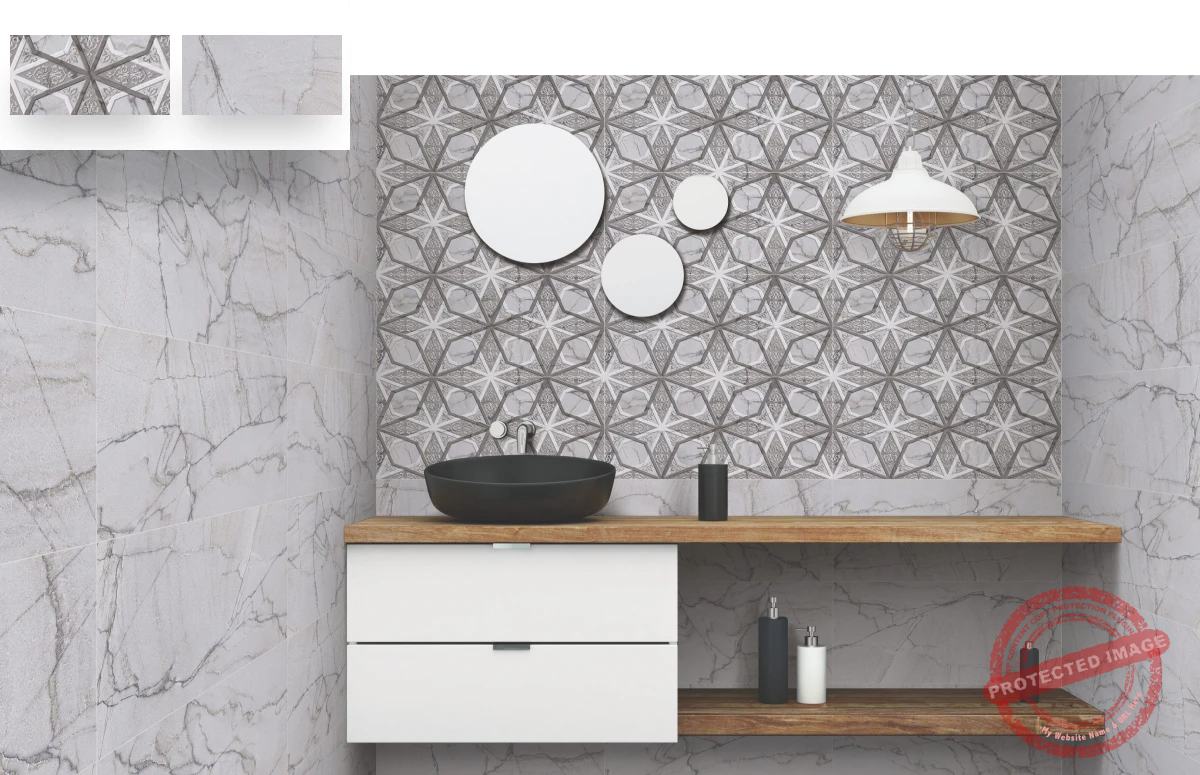

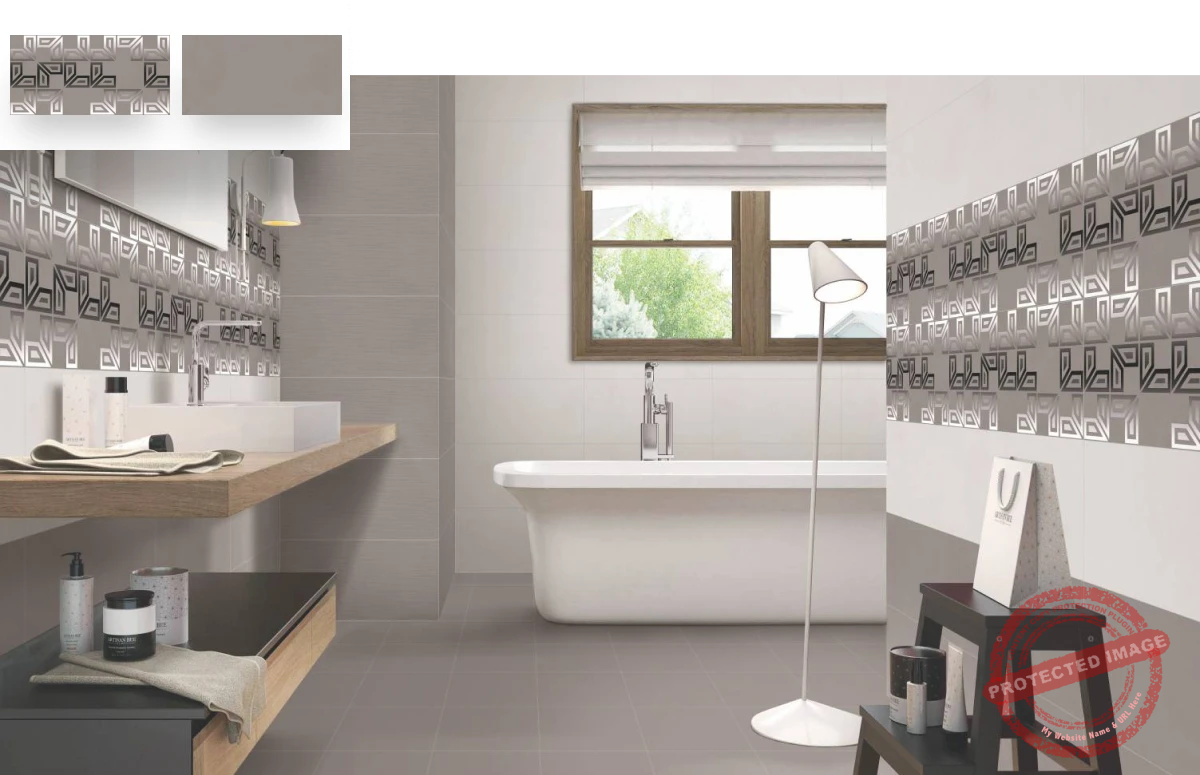

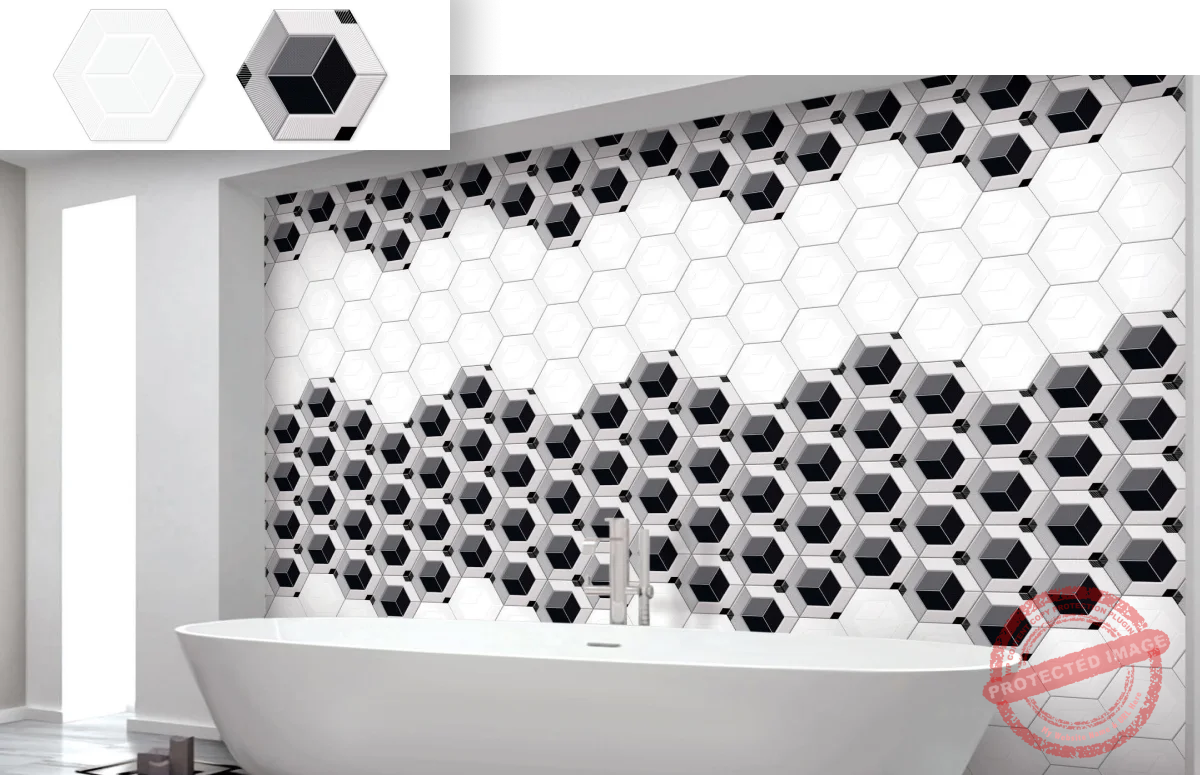

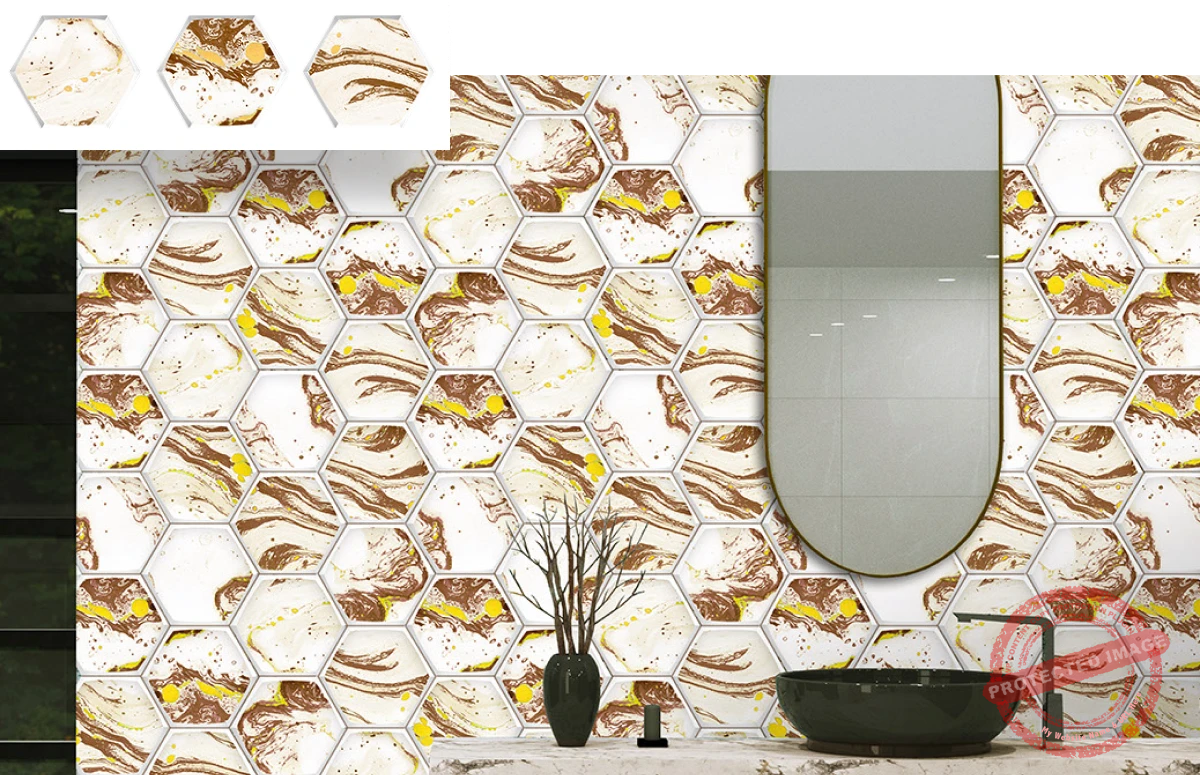

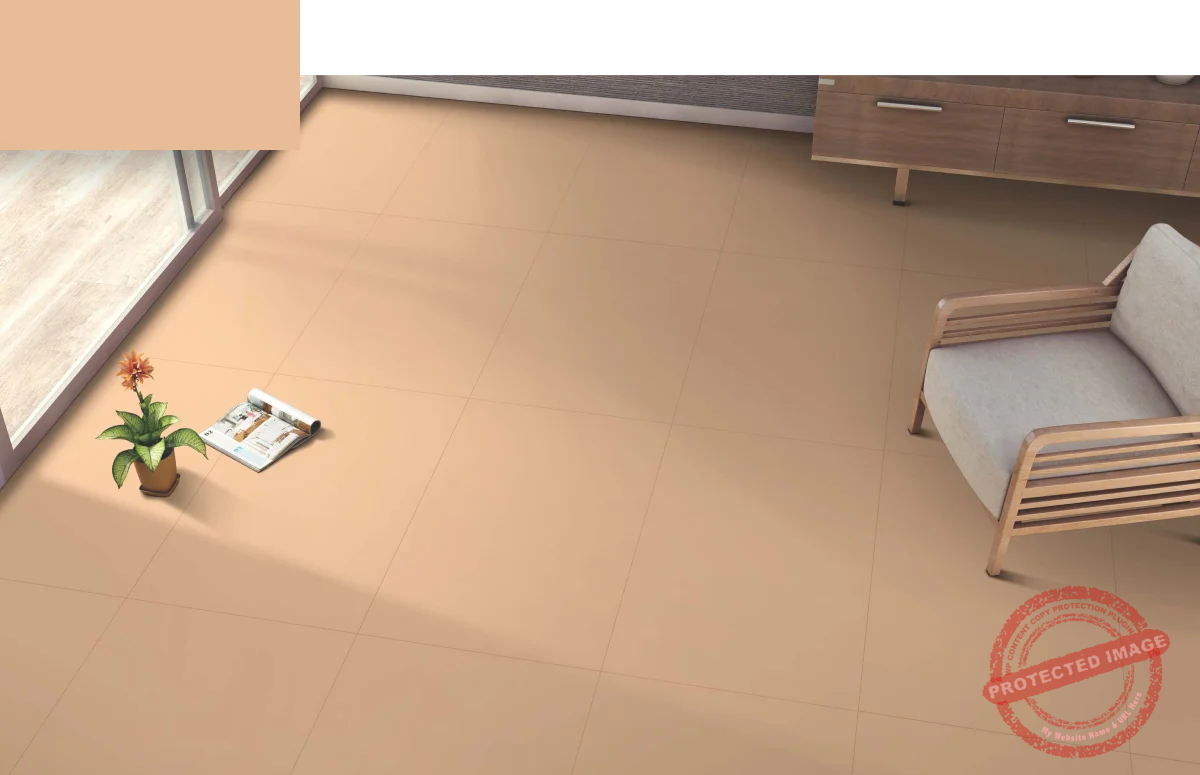

Bathroom Tiles

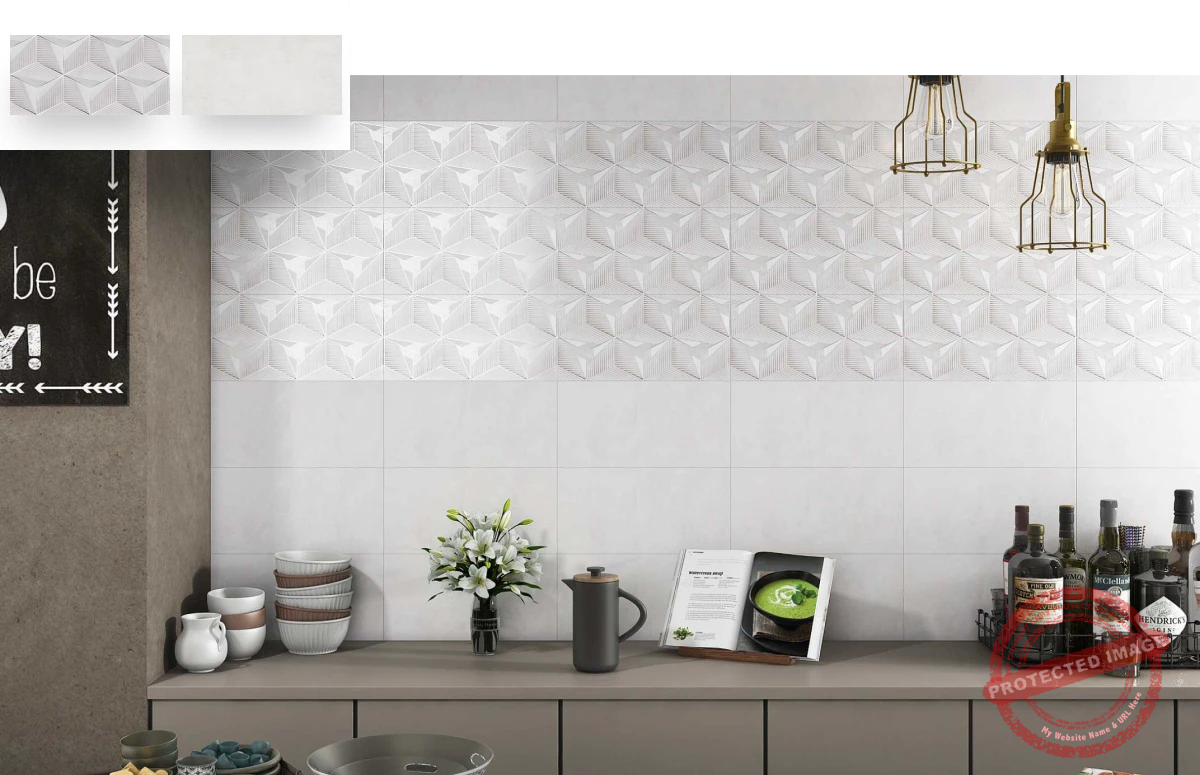

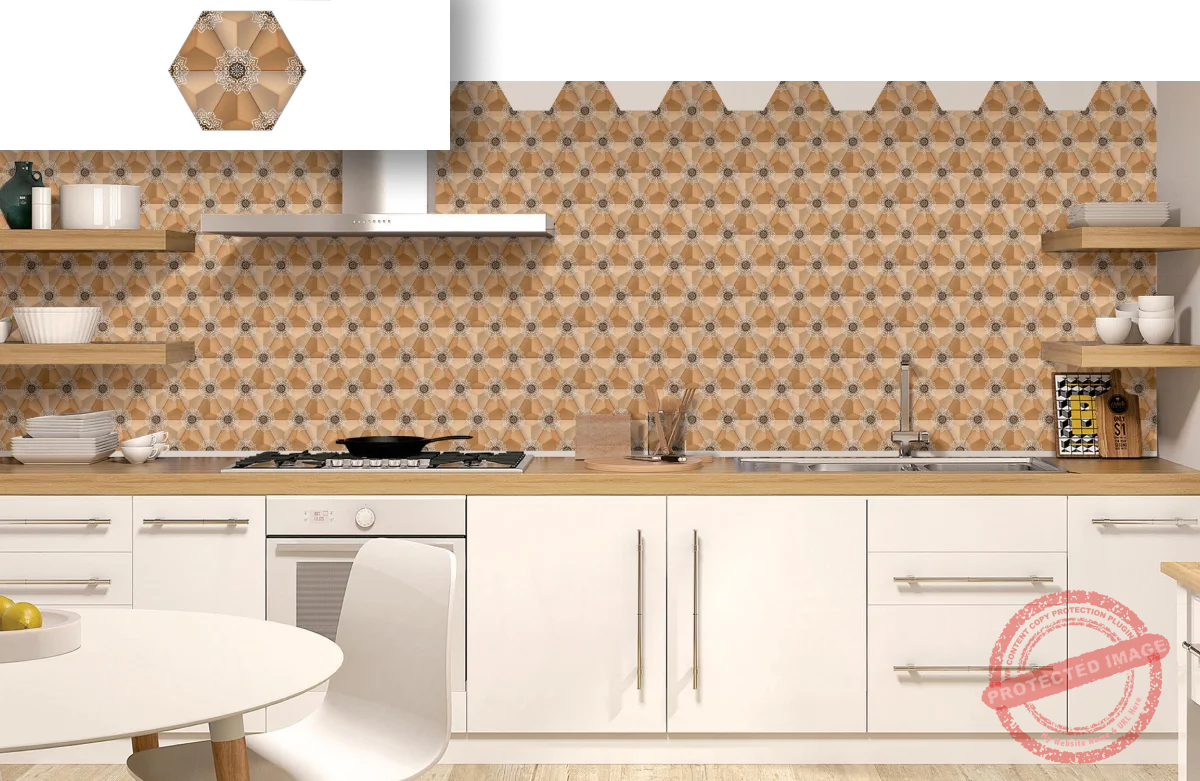

Kitchen Tiles

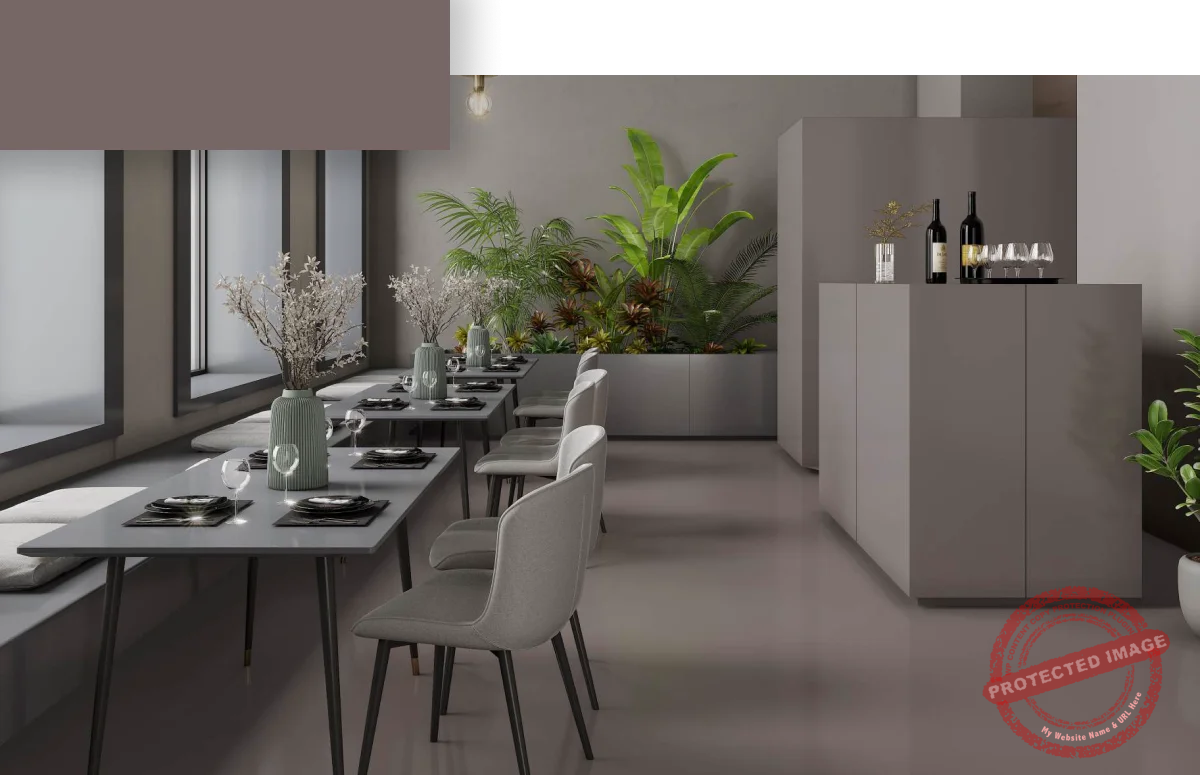

Slab Tiles

PGVT/GVT Tiles

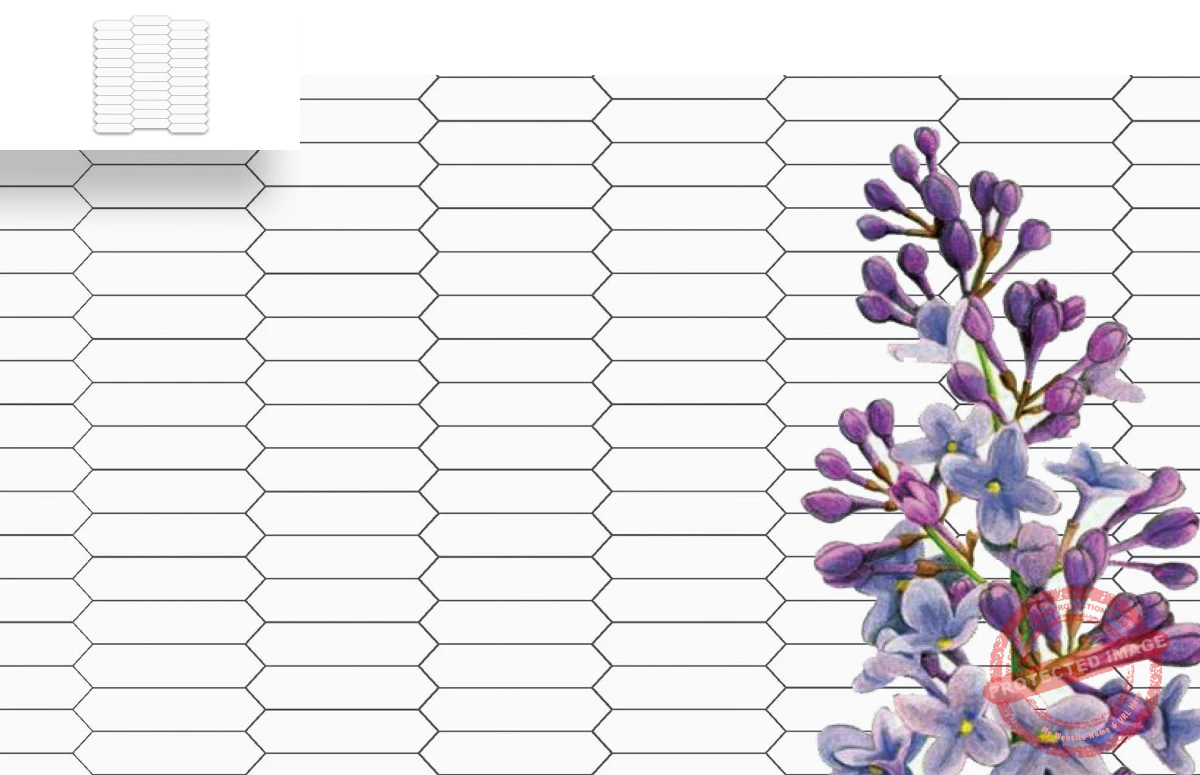

Hexagon Tiles

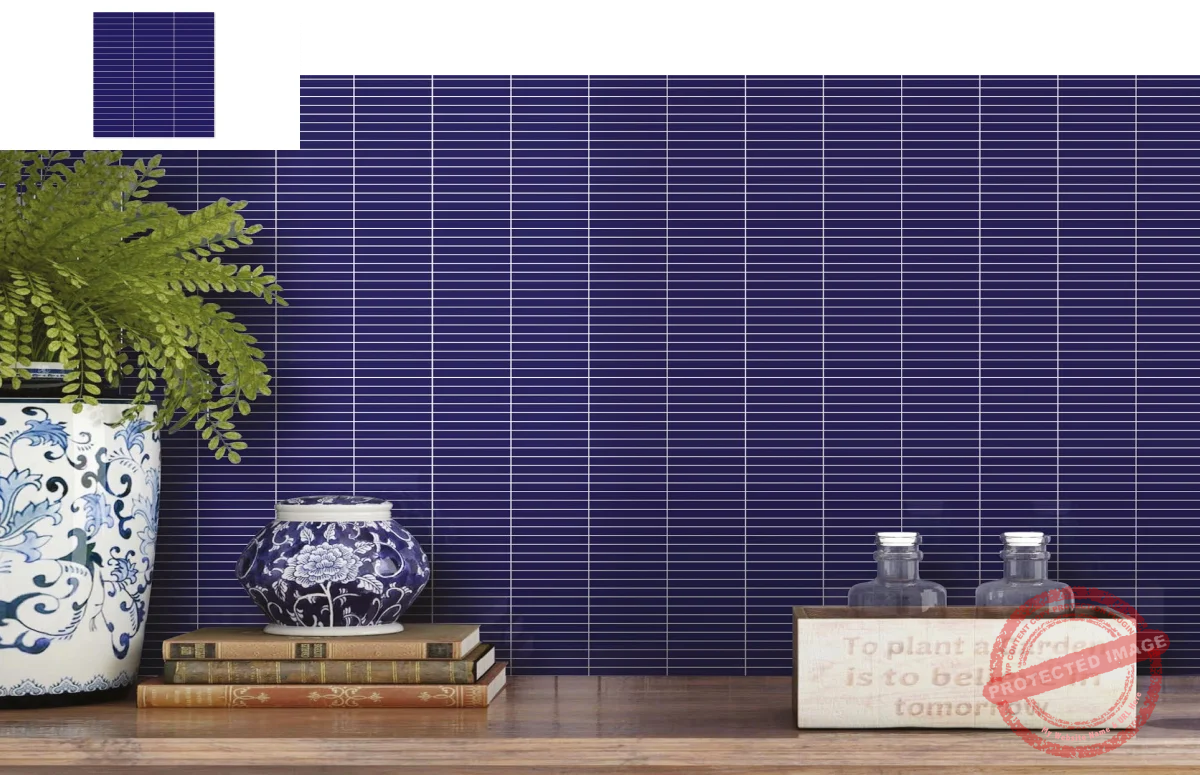

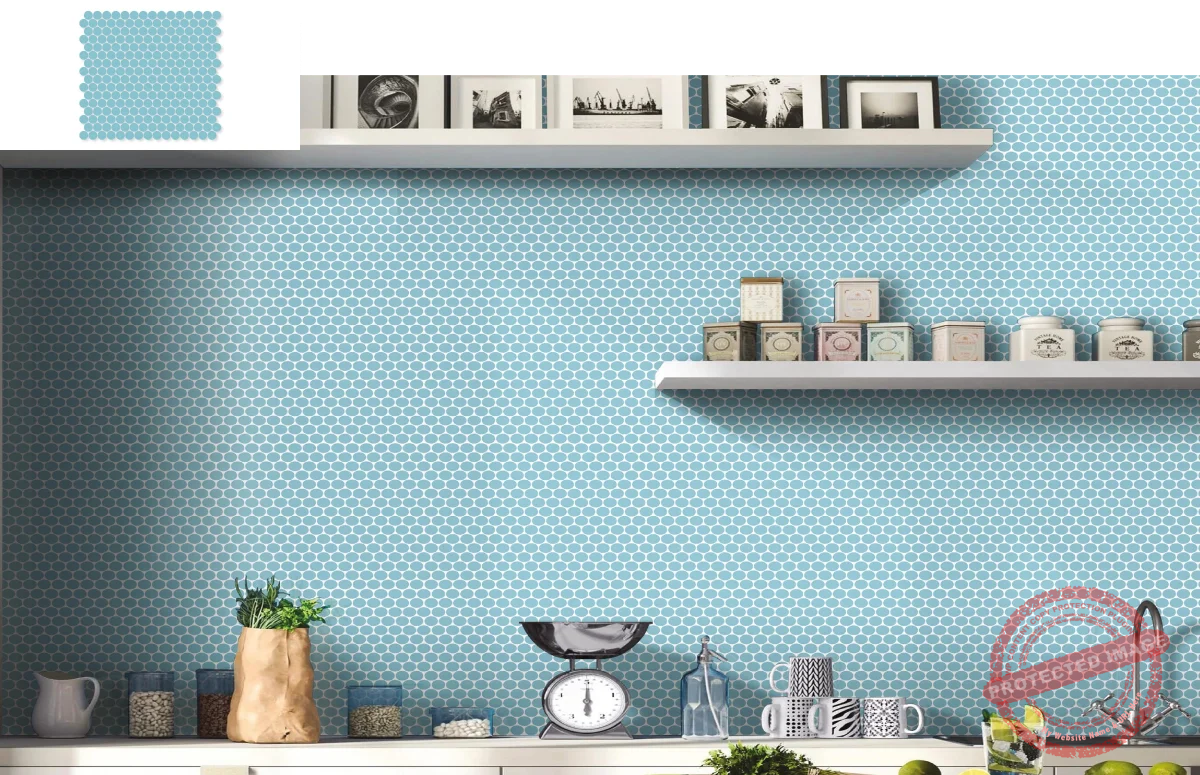

Porcelain Mosaic Tiles

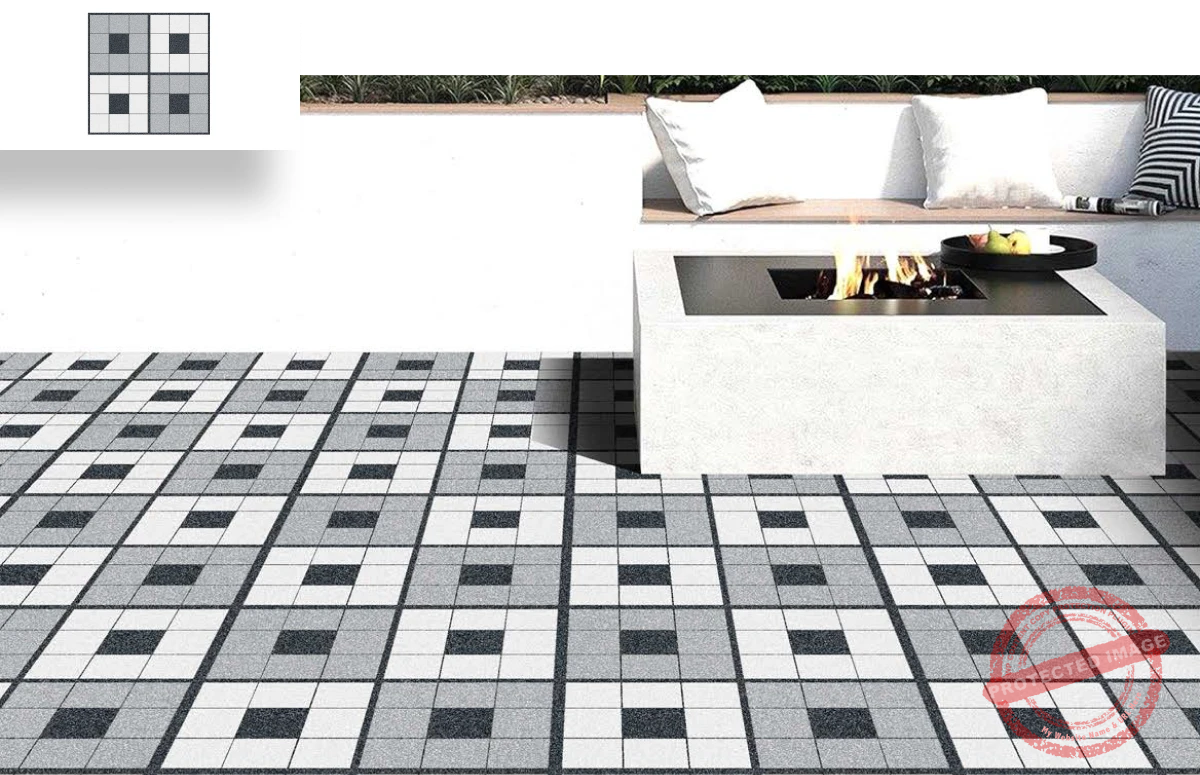

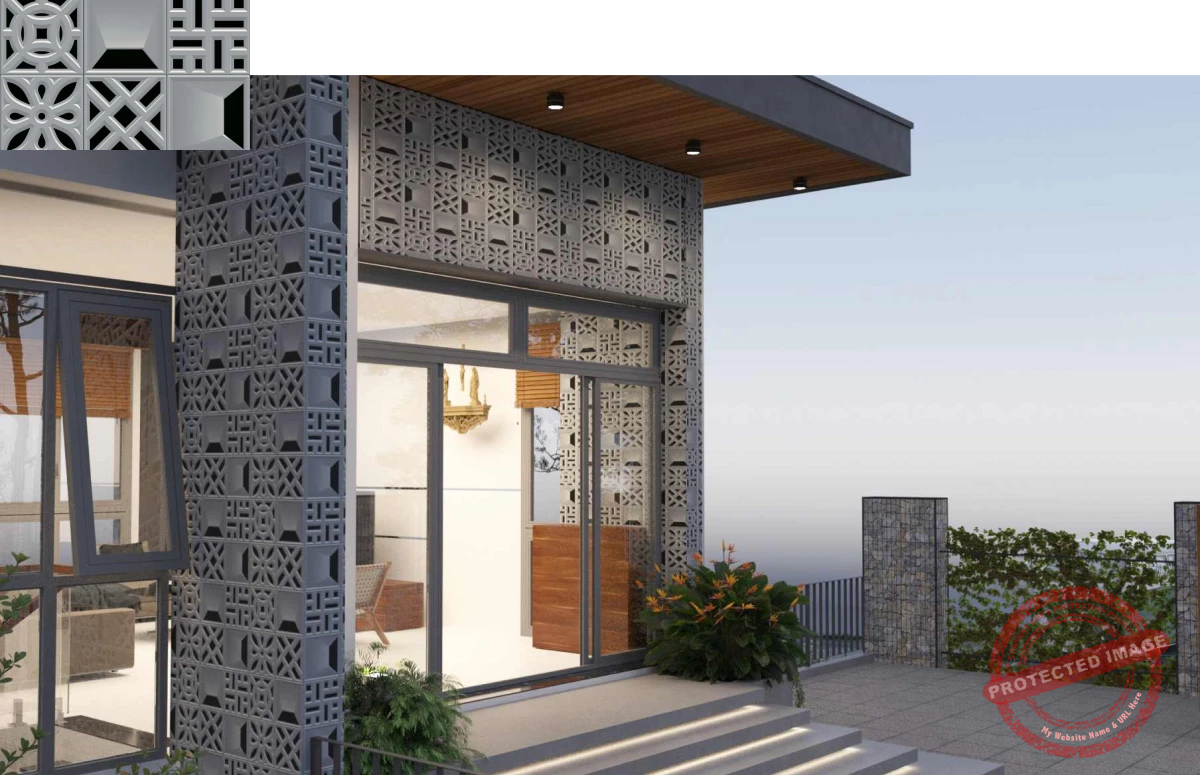

Parking Tiles

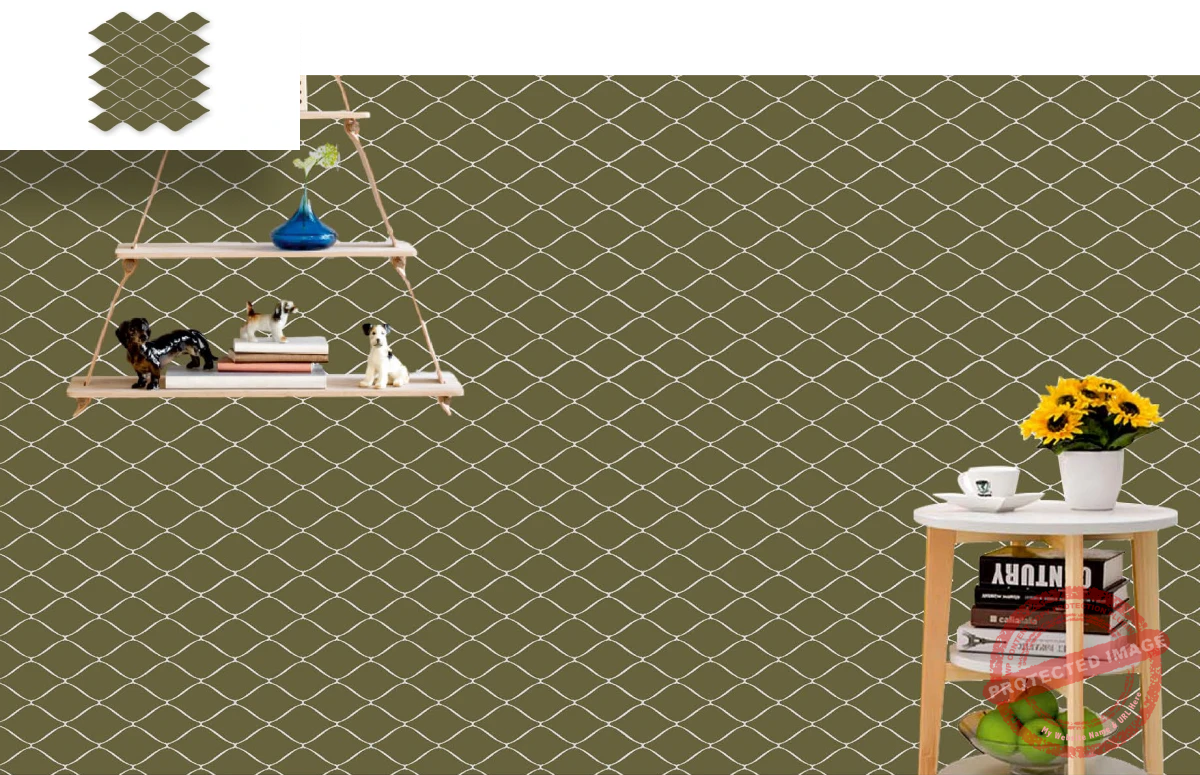

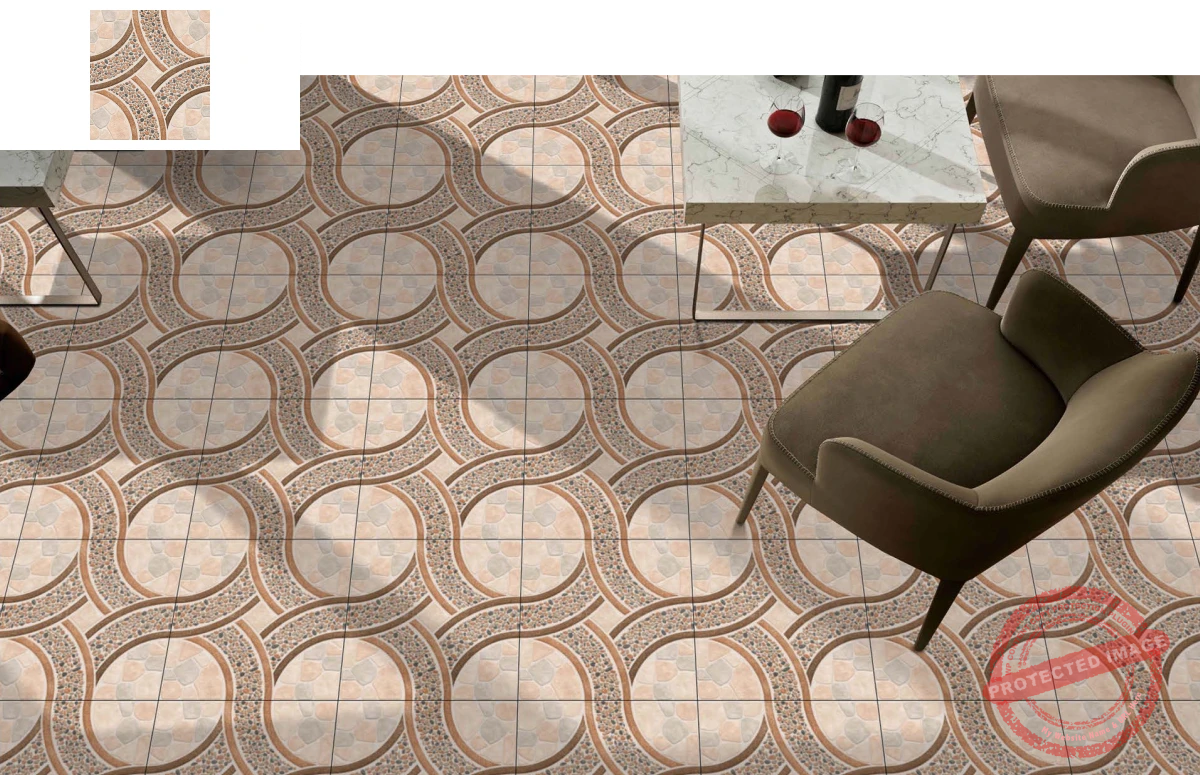

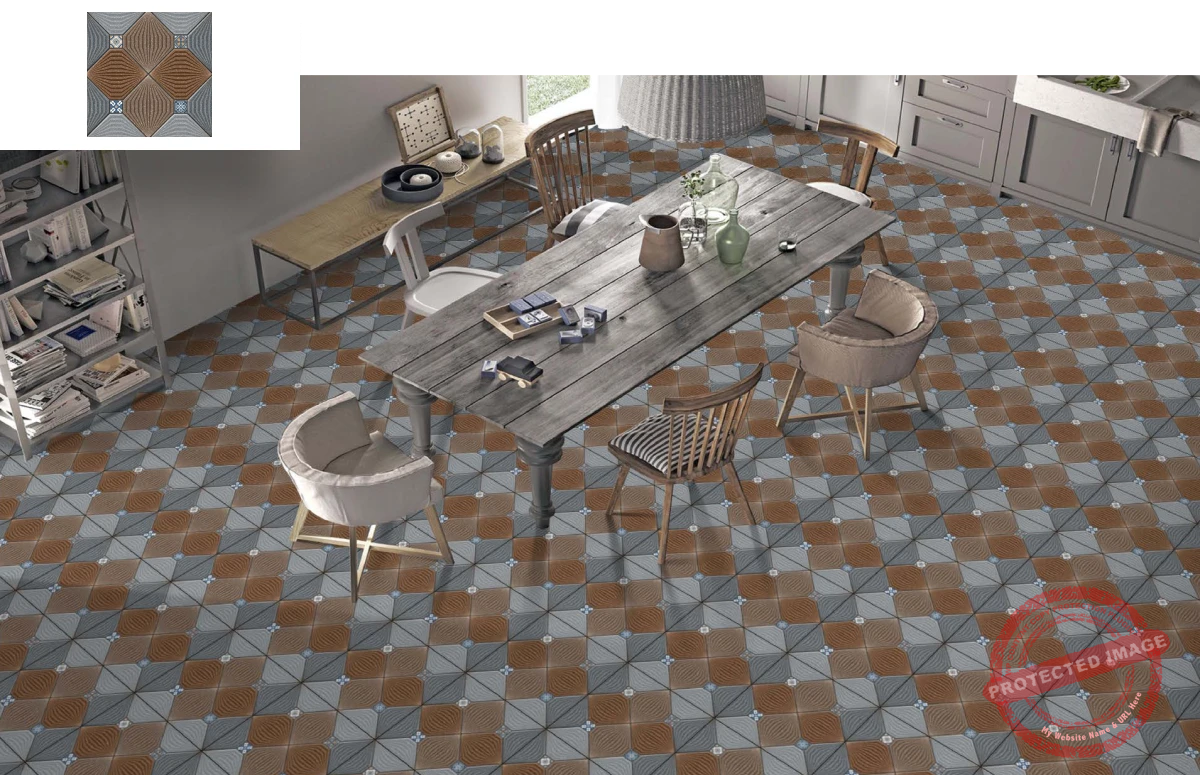

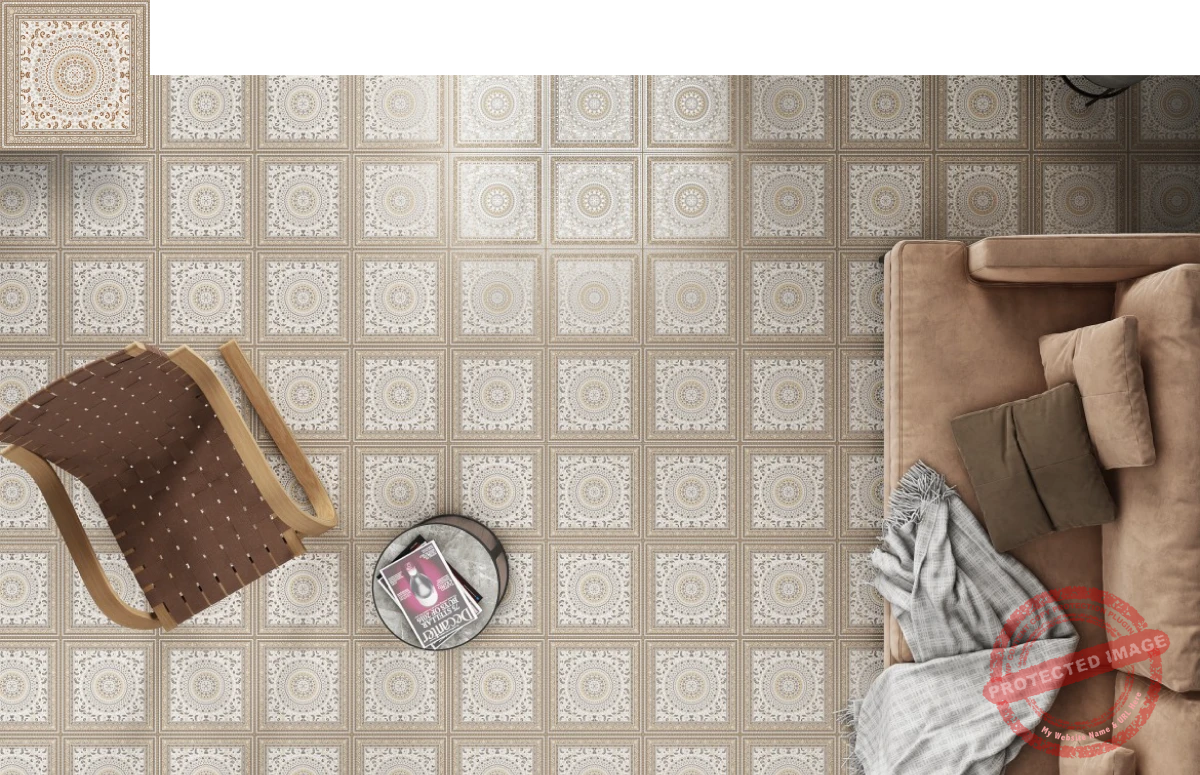

Moroccon Tiles

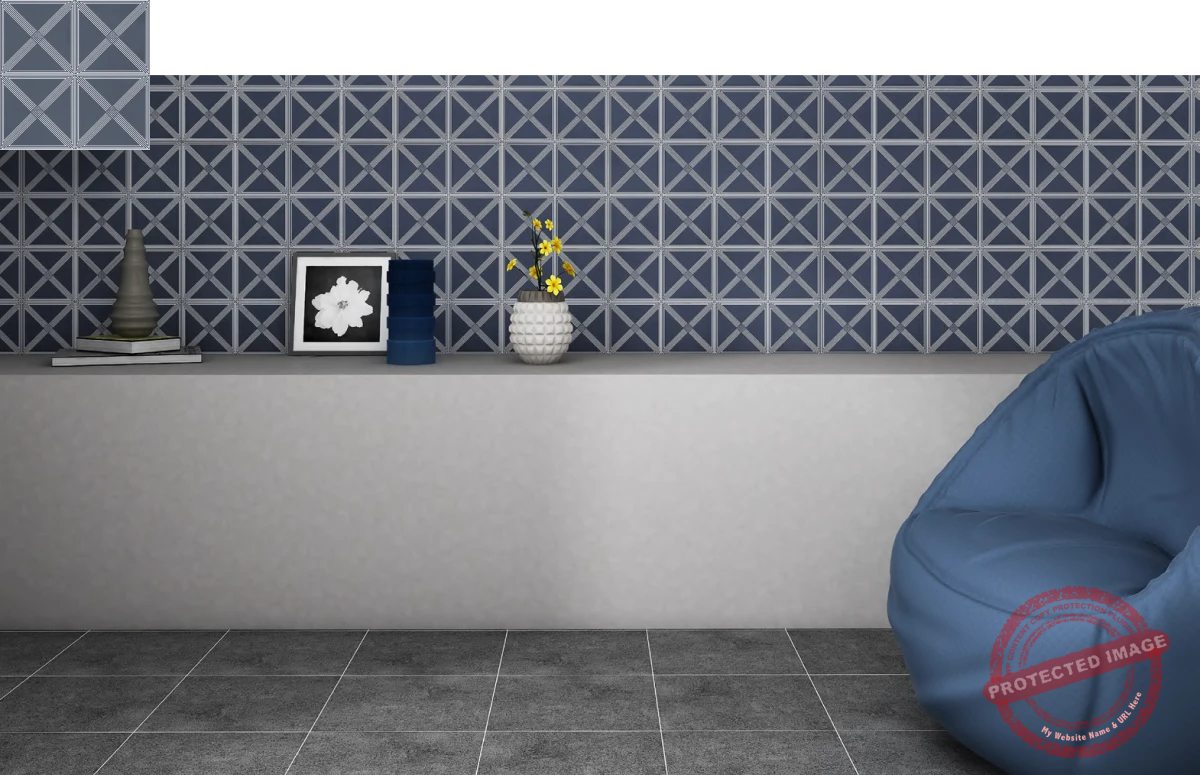

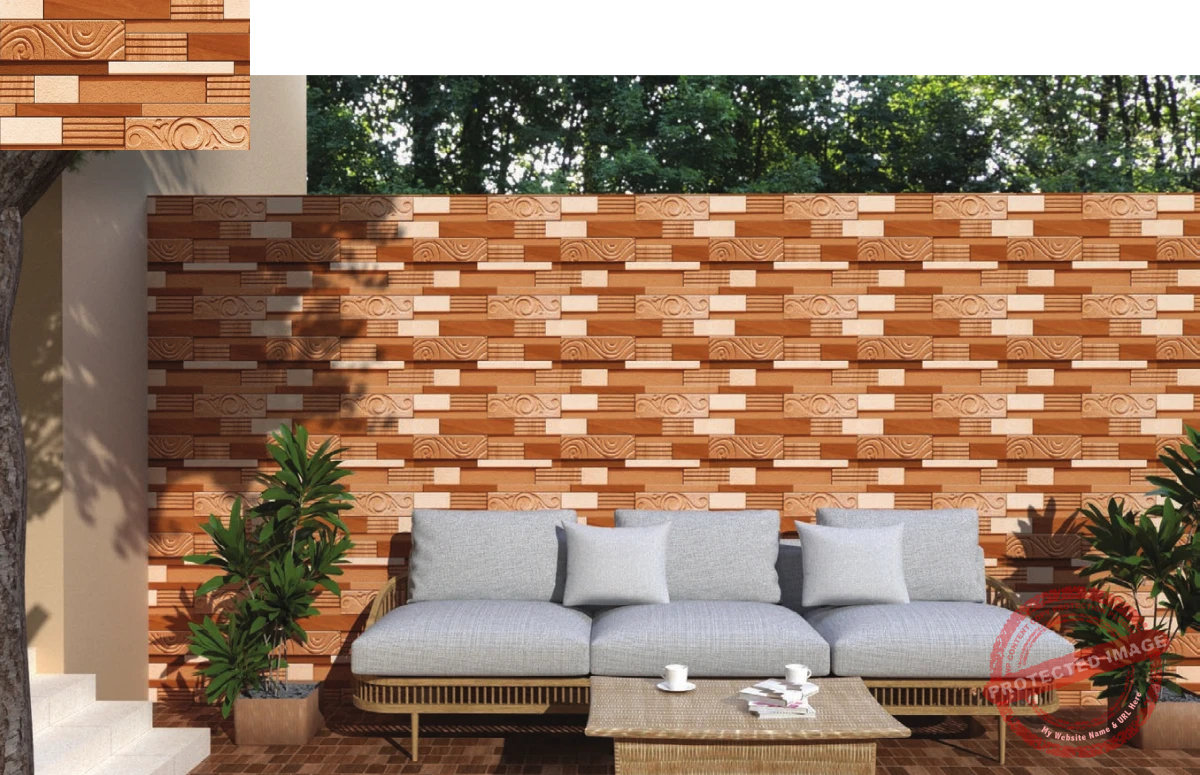

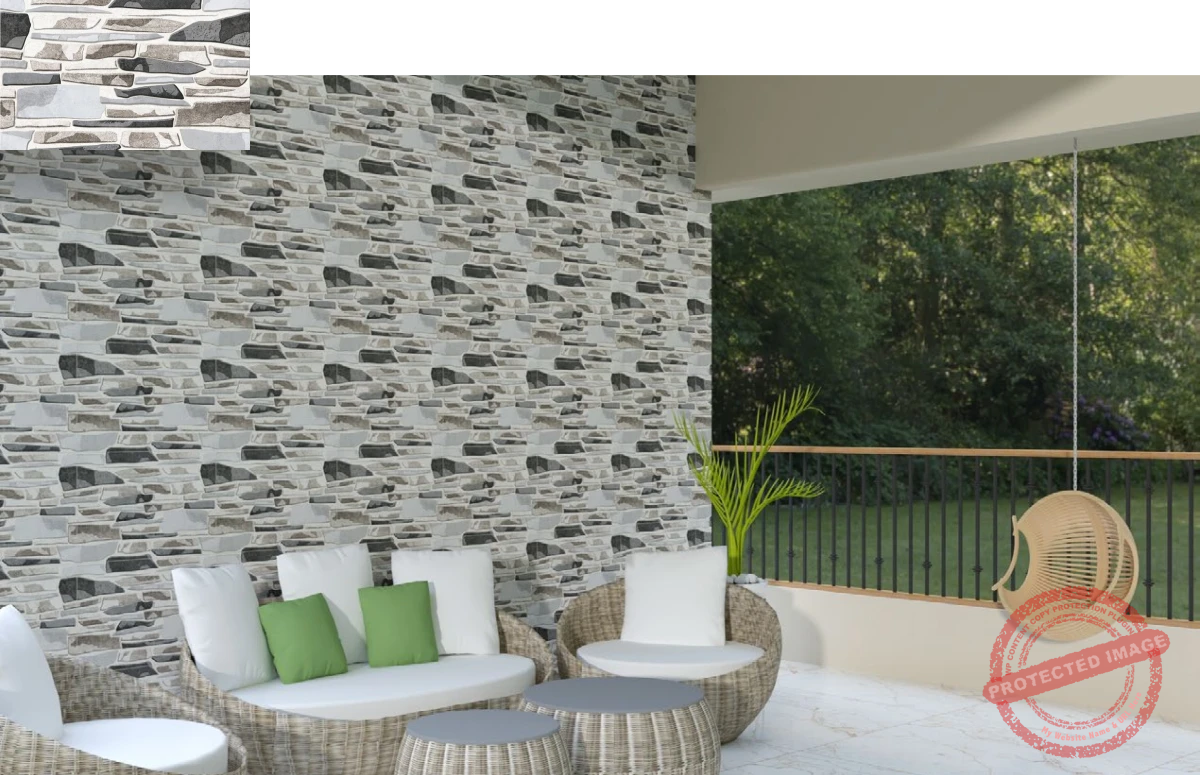

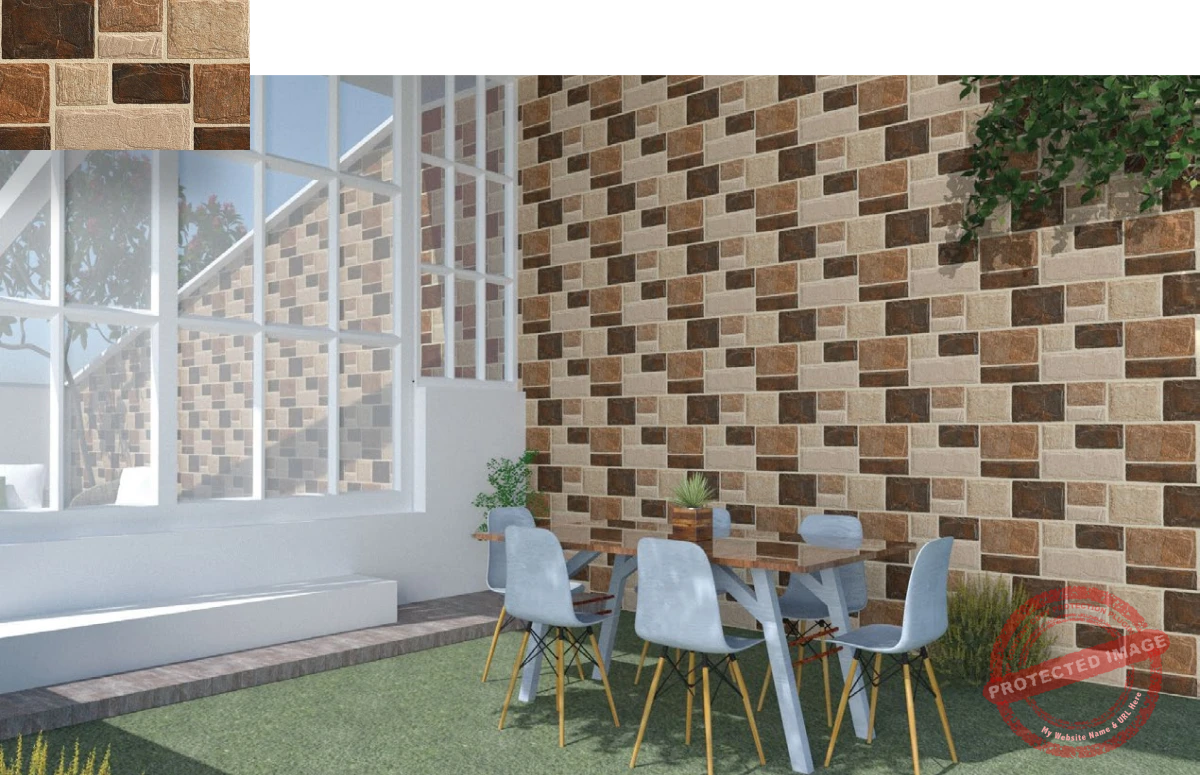

Elevation Tiles

Large Format Tiles

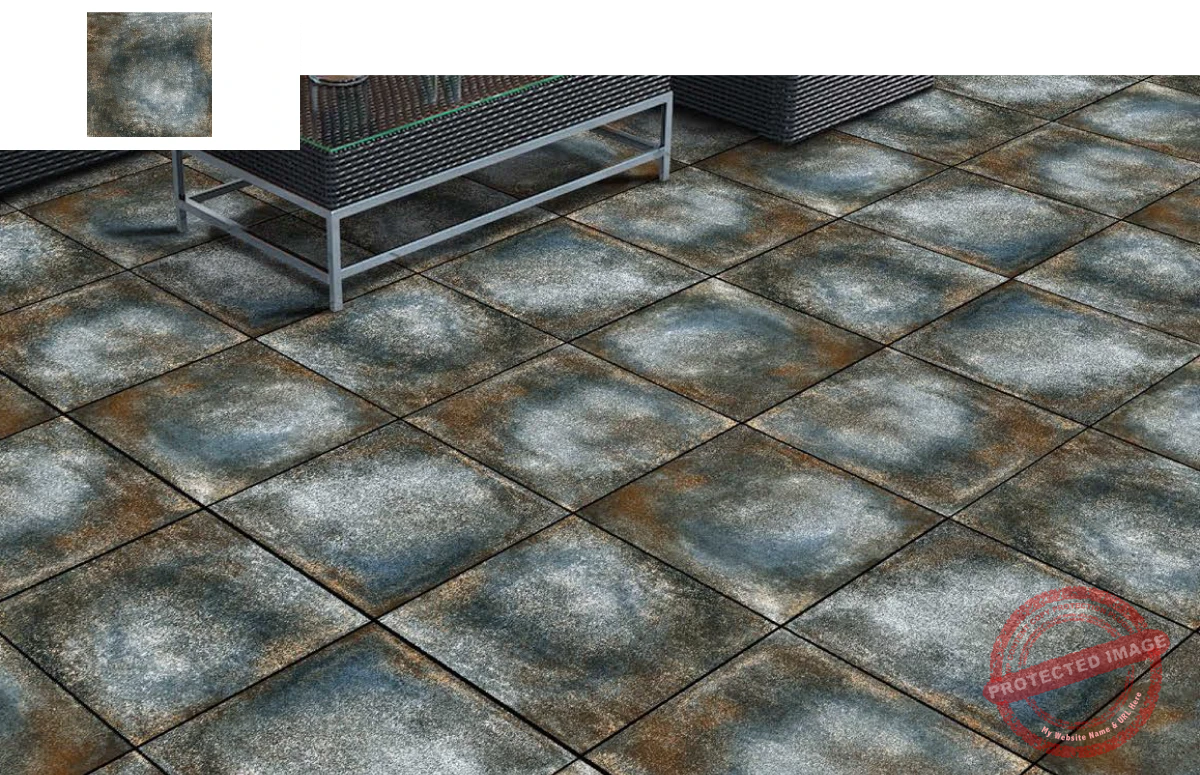

Full Body Tiles

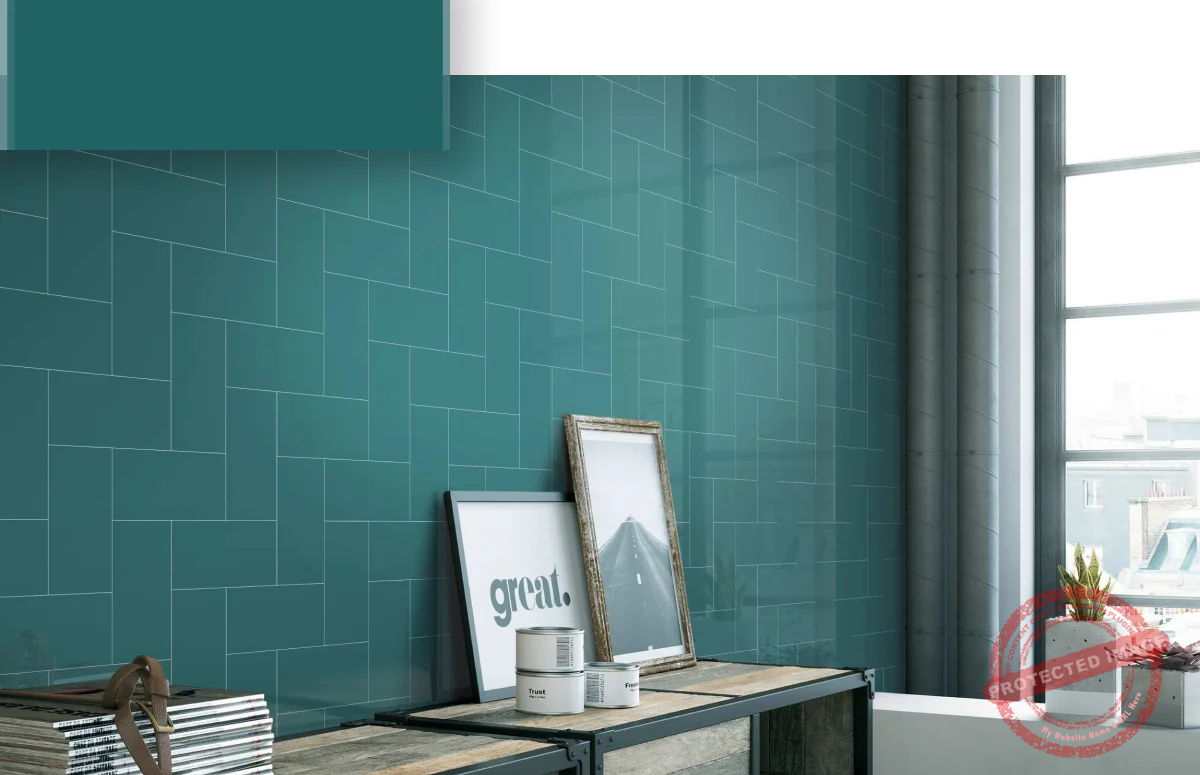

Subway Tiles

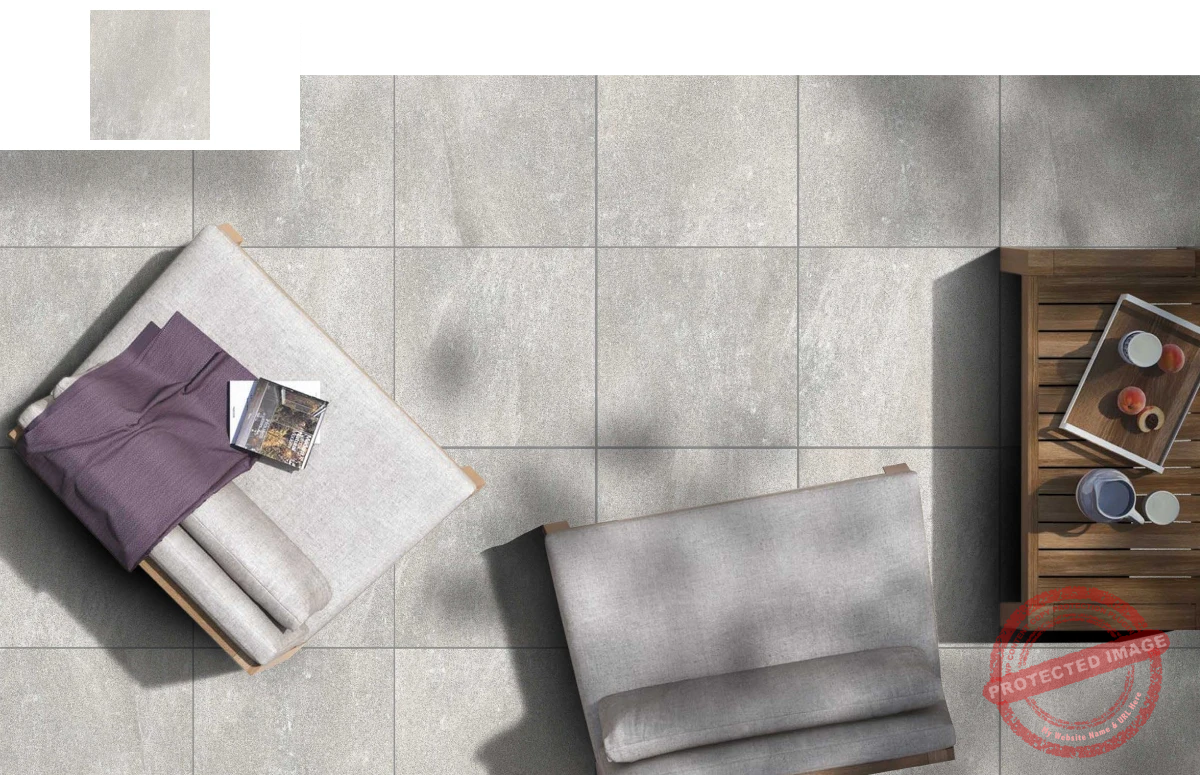

Porcelain Tiles

Double Charge Tiles

Manufacturing Process of Ceramic Tiles

Preparing the Raw Materials

Ceramics are made from three basic ingredients : clay, silica and feldspar A mixture of components used 1. Clay 2. Filler – e.g., quartz 3. Fluxing agent – Feldspar

STEP 01

Batching

Batching or proportioning may be done by volume or by mass. However, proportioning by mass is far more accurate than that by volume.

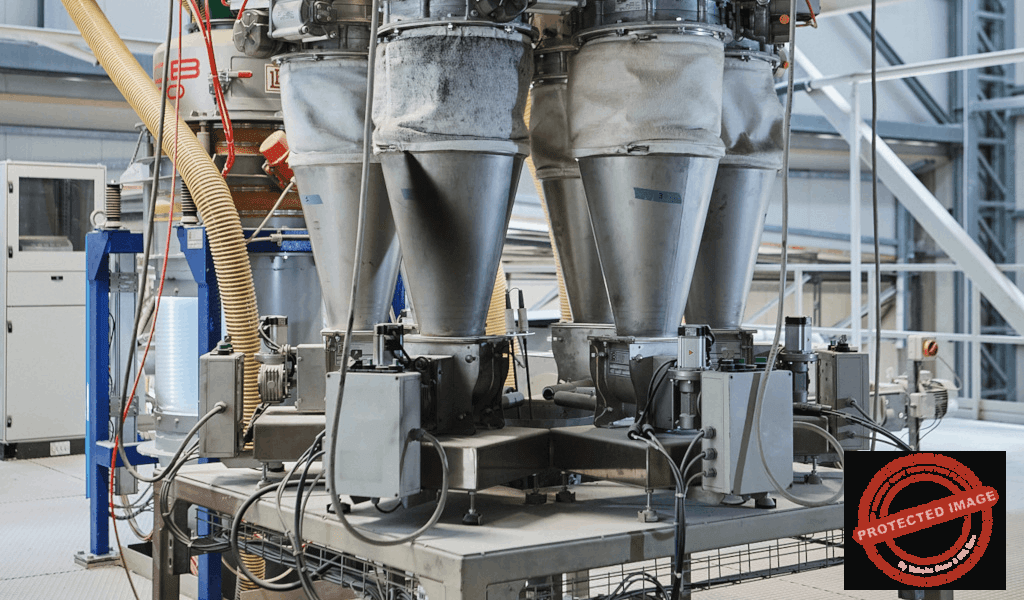

STEP 02

Mixing & Grinding

The grinding of solid raw materials involves a whole series of operations aimed at reducing the size of materials.

STEP 03

Spray Drying

Spray drying is the process that converts the body slip obtained from the mill to a granulate with a size distribution and moisture content suitable for pressing

STEP 04

Pressing

Pressing is the simultaneous compaction and shaping of a powder or granular material confined in a rigid die or flexible mould.

STEP 05

Drying

This is carried out to increase the strength of the unfired tile and also to reduce the risk of tile loss due to deformation as the tile rapidly shrinks or cracks as the steam is rapidly evolved in the kiln.

STEP 06

Firing

Firing is usually the final stage in the ceramic tile manufacturing, at which the weak, unfired, newly pressed piece of tile is transformed into a strong, durable product due to the effect of chemical and physical reactions within the green body during heating.

STEP 07

Finish Production

Once the tiles have been fired, they are carefully inspected for any defects, such as cracks, chips, or uneven coloring. Any defective tiles are discarded. The remaining tiles are then cleaned and polished to give them a smooth, shiny finish.

STEP 08

Sorting

The finished tiles are sorted by size, color, and finish. This ensures that the tiles are easy to identify and select for different projects.

STEP 09

Packaging

The tiles are then packaged for shipping. The packaging protects the tiles from damage during transportation. The type of packaging used depends on the size and weight of the tiles.

STEP 10

Warehousing

The packaged tiles are then stored in a warehouse until they are needed. The warehouse must be climate-controlled to protect the tiles from damage from moisture and temperature extremes.

STEP 11

Dispatching

The tiles are shipped from the warehouse to the customer. The tiles are typically shipped by truck or by rail. The type of shipping used depends on the distance the tiles need to be shipped.